EE projects in general and EPC projects more specifically usually rely on two main elements:

- a performance component that is directly related to the efficiency of the equipment installed

- the operation of this equipment, essentially reflecting how the facility owner uses such equipment.

In an EPC, each contracting parties has access to different knowledge. Indeed, ESCOs naturally know more about equipment performance than the owner or the financier and are in an excellent position to take the retrofit performance risks. On the other hand, building managers has knowledge and control over operational issues such as usage, hours of operation, occupancy, etc. Thus, facility's owner are naturally well-positioned to take responsibility for the operational risks associated with an EE project. Finally, when a third-party financier provides project funding, it has specific information regarding financial investment risks and tolerance factors.

In an EPC project, the contracting parties agree to pool their knowledge into a business transaction and share the cost-benefits of an EE project so that all parties involved win. In that sense, EPC addresses asymmetrical information – one of the most important barriers to EE – by pooling the information in a contractual arrangement and optimally allocating various risks to the party best suited to take them.

M&V activities are at the core of EPC projects realized by ESCOs. They are based on business transactions between parties that include i) an owner where the project is implemented, ii) an ESCO taking care of the project design and implementation, and, iii) sometimes, a third-party financier. Establishing the performance of EE projects and specific equipment may be challenging. Hence the need to rely on well-performed M&V activities. M&V is the process of planning, measuring, collecting, and analyzing data to verify and report energy savings resulting from implementing an ECM.1 But, energy savings are by definition the absence of energy use and subsequently cannot be directly measured. However, energy use can be measured. M&V, therefore, represents the process of analyzing measured energy use before and after a retrofit project to determine savings.

M&V is fundamental to EPCs because the ESCO remuneration is based at some level or totally on the project's performance. To create the necessary trust factor needed for such a scheme to work, the M&V process must be based on an independently developed and recognized methodology and structured framework that allows repeatability, transparency, and adequate validation option of the energy savings for all stakeholders.

Building confidence on EPC M&V with a globally recognized protocol

Until the second half of the 1990s, the underlying concepts and methods for project-level performance assessments were loosely defined in various protocols and guidelines. Eventually, a need emerged to rationalize M&V activities, and the Efficiency Valuation Organization (EVO) was created to develop and maintain the IPMVP. The protocol was established by a worldwide consensus in 1996 and quickly became the gold standard for M&V and the reference in EPC projects as it went hand-in-hand with the emergence and growth of the ESCO industry.

The strength of the IPMVP framework relies on its flexibility. Its framework offers four different options: two focusing on the measurement of specific and isolated ECMs, and two on the impact of multiple ECMs on the building as a whole when the isolation of particular ECMs is not possible or practical.

In EPCs, the choice of an IPMVP option is driven by many factors, including M&V cost and the level of precision needed by the parties involved in a project. Other considerations, such as the type of performance contract (mostly shared or guaranteed savings), will also influence the rigor of the M&V process.

Option A and B

In Option A and Option B, only the performance of a specific ECM is of concern. These options are generally well suited for EPCs, particularly when considering the performance and operations responsibilities assigned to the ESCO and the facility owner.

For the ESCO, M&V activities are usually straightforward since meters are added for isolation purposes. In context, interactive effects between the ECM and other facility equipment can be either measured or assumed immaterial and thus ignored. From the facility owner's perspective, additional benefits may arise since the meters installed to isolate the ECM can be used for operational feedback. For example, the collected data could potentially be used in a split savings scheme with the tenants.

Option C and D

Option C is usually considered more simple and less costly since it assesses the energy performance of an entire facility and therefore relies on energy data typically coming from utility bills.It has to be noted that it is often not the reality. From a purely technical perspective, this option is well adapted for projects where multiple ECMs are installed – which is usually the case of retrofits where savings are expected to be significant – typically higher than 10 % of the total facility energy used before the implementation of ECMs. Options C is also preferable when interactive effects between different ECMs are substantial – a situation that would make M&V with either Option A or Option B very complex and/or cost ineficient.

However, Option C is often ill-suited for EPC projects with an extended contractual period. The longer the contractual period, the higher the risks and costs are associated with the need to adjust the savings calculation.2

Finally, Option D is used in the absence of historical energy consumption data and involves computer simulation. Its application requires a specific skill set. This option is also applied where multiple ECMs are implemented. Option D is often used for new construction, and since EPC projects are mostly retrofits of existing facilities, it is not generally considered. Nonetheless, calibrated simulation techniques, typically used in Option D M&V, are increasingly used in combination with other IPMVP options.

Selecting the best option

The selection of an M&V option in the context of EPC projects depends on the context in which the EE project is implemented (type of facility, type of ECMs implemented, etc.) and must consider the level of uncertainty and related accuracy expected from the savings calculation and the length of the contractual arrangement. Reducing the uncertainty and improving the accuracy becomes a balancing act between the M&V expenditures and the payments made under an EPC.3

In the United States, it was recently observed that EPC projects performed in US Government facilities are increasingly relying on Option B and C and less on Option A. From 1998 to 2008, 70.2 % of total projects' value followed Option A and 18.2 % a mix of Option B and C. For the period 2016-2019, these proportions were 46.2 % and 52.5 %, respectively, marking a clear trend towards more comprehensive and rigorous M&V. This trend towards more ambitious M&V reflects the increased installation of generation units in facilities (including renewable) along with efficiency measures, and by deep retrofit projects with multiple, interactive ECMs.4

Other European experiences show that specific ECMs implemented in the industrial sector mainly relied on Options A and B, reflecting the nature of subsidies programs targeting particular energy usage. As observed in the United States, when EE programs target buildings with multiple ECMs, Option C has been mainly preferred to consider interactive effects between ECMs. More recently, many new public projects in France are undergoing Option C and D M&V.5

M&V is neither complex nor expensive

Despite the flexibility of the four IPMVP options, some claim that M&V is not practical, too expensive, and even impossible have been raised, and the use of deem savings has been promoted in some countries in the context of EPC projects. Proponents of M&V options adherent to the IPMVP on their side base their analyses on a structured cost-benefit approach. Let us have a closer look at these claims:

- Not practical or reliable. It is possible to validate the amount of efficiency gained by using M&V best practices. Although M&V may never be 100% accurate, it has the merit of providing a reliable, repeatable, transparent, and verifiable standardized method needed for any specific purpose while still being conservative.

- Too expensive. The cost of M&V can be adapted to each EE and EPC project and varies based on the required precision level and the investment size. The typical M&V cost is around 3 to 5% of a project's capital cost, impacting the internal rate of return (IRR) of EE and EPC projects by only about 1%. It thus has little or no impact on the economic basis for an investment decision.

- Not possible. While it is true that developing and implementing M&V plans on EE projects may sometimes be complex and can be technically challenging for many to do, it is fundamentally wrong to assume it is impossible to do. M&V is always possible. In most cases, and with the appropriate skills and knowledge, developing and implementing an M&V plan is relatively easy to do.

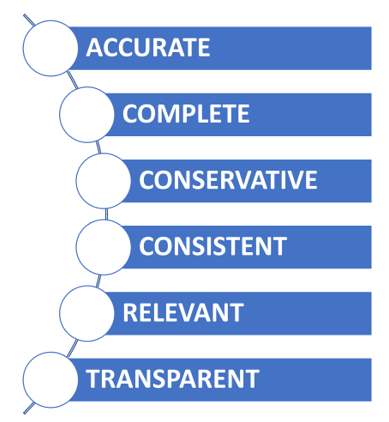

M&V Principles6

Good M&V practice in the context of EPC projects is not different from any other usage of M&V and is therefore based on six fundamental principles. M&V must be accurate, complete, conservative, consistent, relevant, and transparent.

The accuracy of measured savings should be evaluated and agreed to by the ESCO and the facility owner (and the financing party if applicable) as a part of the project development and reflected in the M&V Plan. Of course, M&V costs should be modest relative to the monetary value of the savings being evaluated and at the same time be consistent with the financial implications of over or under-reporting a project's performance. Professional judgment must be exercised, and consideration of all reasonable factors that affect accuracy is a guiding principle of IPMVP.

To be complete, the reporting of energy savings should consider all effects of a project. M&V activities to be integrated into the EPC process outlined in the M&V Plan will indicate which effects should be quantified through measurement while estimating others. This will depend mainly on which IPMVP option is selected and the desired level of accuracy sought.

To remain realistic, and where judgments are made about uncertain quantities, M&V procedures should be designed to estimate as precisely as needed the savings, so they are not overstated responsibly and therefore be considered conservative. This means that an assessment of a project's impact should be made to assure its energy-saving benefits are reasonable and conservative, considering the level of confidence in the estimation.

Measured energy savings and the reporting of a project's energy performance should be consistent and comparable across different types of EE projects, various energy management professionals for any project, different periods for the same project, or EE projects and new energy supply projects. However, we should keep in mind that "consistent" does not mean identical since it is recognized that any empirically derived report involves judgments that may not be made identically by all reporters.

M&V activities must also focus on the most relevant factors. The savings determination should be based on current measurements and information about the facility where the project occurs. This determination of saving effort must measure the performance parameters of concern or that are least well known, while other less critical or more predictable parameters may use estimated values.

Finally, all M&V activities must be transparent and should be clearly documented and fully disclosed. Full disclosure should include a presentation of all of the elements of an M&V Plan and saving reports. Data and information collected, data preparation techniques, algorithms, spreadsheets, software, assumptions used, and analysis should follow standard practices as closely as possible, be well formatted and documented – such that any involved party or outside quality assurance reviewer can understand how the data and analysis conformed to the M&V Plan and savings reporting procedures.

No EPC without M&V and no M&V without an M&V plan

No pilot would take a plane without first consulting the maintenance logbook, checking the fuel level, preparing a flight plan. Similarly, nobody should enter into an EPC contract without first checking that the proposed technologies are proven, that the technical team has the necessary skills to realize the EE project, and that the contract includes a detailed M&V strategy to develop adapted plans to be accepted by all concerned parties prior to the implementation of the project.

The M&V Plan is the ESCO and facility owner's (and all other stakeholders) operational guide throughout an EE project's performance period. Such a plan is site-specific; it states which IPMVP option has been retained and details the M&V method used for each ECM. Most importantly, the M&V Plan will provide a well-defined baseline energy use that will be the foundation of the whole M&V process. This must be done before implementing the ECMs, as the baseline cannot be measured after the fact. The M&V Plan will also provide a clear description of the calculation and verification methods used to measure the energy use during the performance period.

As mentioned before, energy savings are the absence of energy used and cannot be measured and are thus "unknown." Therefore, they must be calculated with as much precision as possible, considering there will always be a certain level of uncertainty. There will always remain a residual risk that cannot be "controlled" by either party. These are risks associated with different aspects of the project including weather conditions, fluctuating energy prices, disasters, pandemics, etc. These risks are thus assumed to be evenly shared between the building owner and the ESCO. In addition to helping manage the risks, an adequate EPC M&V Plan(s) will minimize a project's uncertainty. In performance contracting, it is because of this uncertainty that ESCO will usually guarantee the savings at 80-85% of projected savings for projects.

M&V needs expertise

We discussed earlier the notion of information asymmetry between the ESCO and facility owners. This is particularly relevant when we consider who takes responsibility for the conduct of M&V. The M&V principles stated above must be attended with adequate skills by individuals who will exercise their professional judgment. There are two approaches to performing M&V in EPCs.

M&V in the context of EPC can be done by any party that has the expertise to do so. Often in EPC projects, the M&V is done by the ESCO and subsequently validated by the facility owner. This is the case because the ESCO has more experience in performing energy savings determinations. While it is reasonable to think that ESCOs have M&V experts on staff, it is likely not true for the customer. Hence, M&V performed by the ESCO may be perceived as biased by customers and can often limit the use of EPC as such clients may be reluctant to use such schemes that they perceived to be not impartial. Thus, the ESCO's customer should consider retaining a third-party expert or project facilitator's services to assist during the design, implementation, and performance phases of an EE project. Such assistance may include the initial review of the M&V Plan(s) and potentially analyzing subsequent savings reports.

Alternatively, it can be performed by an independent third party. An EPC requires that both parties believe that the information on which the payments are based is valid and accurate. An experienced independent third party may be helpful to ensure agreement of measurement validity. Should conflicts arise over the project payback period, this third party can help resolve differences. Third-party savings verifiers are typically engineering consultants with experience and knowledge in verifying savings, EE technologies, and, where relevant, in reviewing energy performance contracts.

EPC’s project M&V cannot be automated or otherwise be reduced to ticking predetermined boxes into a checklist. Between the ESCO, the customer, and the third-party financier (when applicable), only skilled and educated experts can play a meaningful and valuable role within an EPC project.

There are different levels of education needed for individuals involved in M&V. As a starting point, knowledge and understanding of the IPMVP framework, M&V concepts, and IPMVP options are required and necessary for many situations but not sufficient in others.

In many cases, particularly in the context of EPC projects, professionals must demonstrate practical skills in applying the IPMVP, particularly in the preparation of M&V plans and in exercising their professional judgment when needed. Solid expertise of interactive effects between EEMs and competencies in performing and analyzing investment-grade audits are also required for third-party experts.

Advanced and specialized M&V training is also necessary for different types of projects. For example, performing M&V for industrial processes and manufacturing applications is different than M&V for buildings. An expert in industrial M&V may not have sufficient knowledge to perform M&V in facilities and vice versa.

Capacity building is therefore crucial for ESCOs, facility owners and managers, and third parties involved in financing EPC projects. The role of M&V advisors and experts should not be underestimated for successful EPCs.

Conclusion

Facility owners around the world are increasingly challenged by energy transition concerns while confronted by rising energy needs. The implementation of ECMs allows for curbing rising energy costs while strongly contributing to the needed decarbonization of our economies. EPC has proven to be very effective in implementing EE projects in all type of facilities. M&V plays a crucial role in EPC as it demonstrates how the energy savings are linked to the remuneration of the ESCO implementing the project.

M&V in the context of EPC is neither complex nor expensive when conducted within a rigorous framework. The IPMVP offers four options to reflect the context in which an EPC project is undertaken and consider the level of uncertainty and related accuracy expected from the savings calculation. Conducted by experts who follow the six M&V principles and establish M&V plans adherent to the IPMVP, M&V then becomes a risk reduction strategy for all parties involved in EPCs.

EPC will continue to grow worldwide and be successful as long as M&V is performed and conducted based on state-of-the-art knowledge and expertise. The need to develop M&V expertise within all stakeholders' teams will become more and more critical to enable the growth of EPC and enable the mechanism to play its role in the global energy transition and reduction of carbon emission reductions.

REFERENCES

1. Core concepts – International Performance Measurement and Verification Protocol. EVO 10000-2016. Section 3 “Terms & Definitions”.

2. For an extended discussion on routine and non-routine adjustments for option C, please see: IPMVP Application Guide on Non-Routine Events and Adjustments, EVO 10400-1:2020.

3. In the FEMP M&V Guidelines 4.0 used for federal government EPC projects in the United States, it is stated that the “…choice and use of a specific option are determined by the level of M&V rigor required to obtain the desired accuracy level in the savings determination and are dependent on the complexity of the project, the potential for changes in performance, each energy conservation measure’s saving value, and the project’s allocation of risk between the ESCO and the customer.”

4. Coleman, P., Earni, S., Slattery, B. and Walker, C., 2020. M&V in ESPC: The U.S. Federal Experience and Implications for Developing ESPC Markets. In: energise 2020 ENERGY INNOVATION FOR A SUSTAINABLE ECONOMY. [online] Hyderabad, India: Alliance for an Energy Efficient Economy (AEEE), pp.216-221.

5. Magnet, Daniel. Personal communication on projects conducted in Switzerland, France and Belgium. September 1, 2021.

6. This section draws heavily on section chapter 4 of the IPMVP Core Concepts – EVO 10000 – 1:2016.

This article was written for EVOs M&V Magazine by Denis Tanguay, EVO Executive Director, and Pierre Langlois, President of Econoler, and Vice-Chairman of Global Esco Network and Past-President of EVO.